Bottled water coolers can lead to numerous issues related to cost, environmental concerns, and health risks. Filtered water coolers, by contrast, are like having the convenience of a miniature water filtration plant in your workplace, filtering and purifying water directly from the building’s water lines. Organizations are increasingly making the switch to filtered water coolers in order to drive efficiencies, maintain employee health, and enhance sustainability initiatives.

1. Cut Costs

AVOID THE MARKUP ASSOCIATED WITH PLASTIC JUG DELIVERY

Eliminating the costs of water delivery provides savings for all workplaces from Wall Street to Main Street! In fact, the larger the workplace (and the more bottles consumed), the greater the savings.

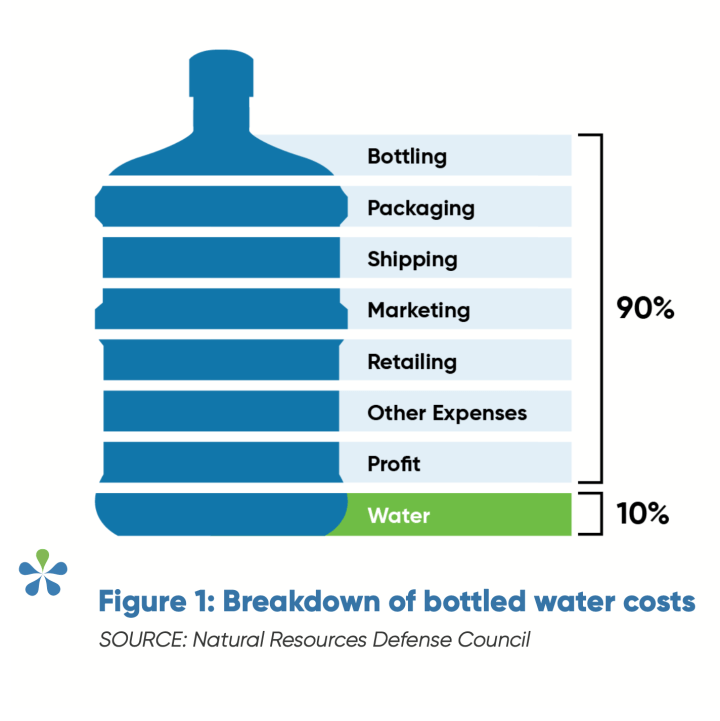

Considering the numerous costs passed along the water delivery supply chain to the end user, it is easy to understand why water delivery is so expensive and why filtered water coolers provide a more cost-effective solution.

If your office pays for water delivery, you are subsidizing:

- The costs associated with manufacturing plastic jugs and filling them with water at bottling plants;

- The cost of shipping 5-gallon water jugs from the bottling plant to distribution centers; and

- Fuel and labor costs of delivery trucks hauling jugs from the distribution center to your workplace.

INCREASE EMPLOYEE PRODUCTIVITY

Freeing workers from managing plastic jug inventory leads to savings in the form of productivity gains. Managing water delivery service is time consuming. Large organizations wrestle with the logistics of keeping track of plastic jugs, knowing the exact location of each cooler, and reordering jugs to prevent running out of drinking water.

Each time additional bottles are delivered to a location, someone needs to meet and, often, escort or supervise the delivery person. Eliminating bottles also means fewer people coming in and out of your building, which lowers the risk of spreading COVID and other diseases.

2. Improve Sustainability

WATER DELIVERY HAS A MASSIVE ENVIRONMENTAL FOOTPRINT

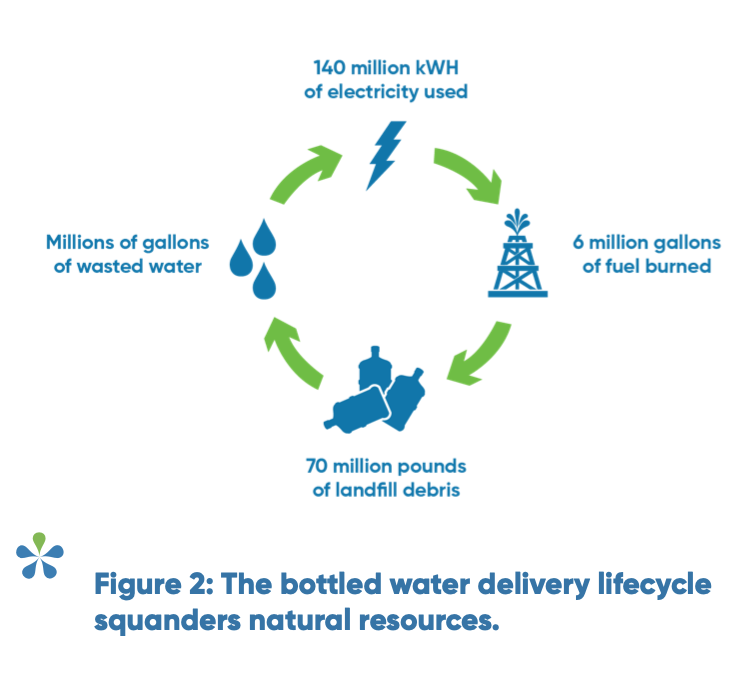

The production and delivery of 5 gallon plastic jugs consumes a staggering amount of electricity, burns millions of gallons of fuel, and releases tons of CO2 into the atmosphere.

Evidence suggests that as much as 80% of all plastic water jugs end up in landfills as well as industrial waste from bottle manufacturing and packaging.

It takes 2 to 5 jugs of water to manufacture a plastic jug from start to finish. Another bottle’s worth of water is then consumed to fill the jug in the bottling process.

It is easy to see how, on an individual office/workplace level, participating in the water delivery supply chain increases a firm’s carbon footprint. Eliminating the costs of water delivery can significantly reduce your business expenses and can help reduce your company’s environmental footprint.

All told, the filtered water cooler industry has had the same impact on greenhouse gas reduction as planting millions of trees all over the world.

3. Enhance Employee Wellness

LIFTING 43-POUND PLASTIC JUGS PUTS UNNECESSARY STRAIN ON YOUR WORKFORCE

5-gallon water jugs weigh an astonishing 43 pounds. To put the weight of these plastic jugs in perspective, that’s the same weight as an 18-foot canoe!

As simple as it may sound, the vast majority of workers who replace these jugs have no training on proper technique for heavy lifting and are in jeopardy of suffering a workplace injury. For most businesses, asking office employees to do this manual labor adds unnecessary risk to operating costs.

Filtered water coolers eliminate the effort needed to replace 5-gallon bottles which allows firms to mitigate one source of workers’ compensation risk in their organizations.

KEEPING BOTTLED WATER COOLERS CLEAN AND SANITARY IS LABOR INTENSIVE AND IMPRACTICAL

Plastic jug water coolers are open systems – in other words, they constantly interact with their environment and are thus vulnerable to bacterial growth.

When people replace the bottles, they add germs or bacteria to the water supply when handling the top of the bottle. Similarly, there are microbiological contaminants in the air that can come into contact with the water supply, resulting in bacteria growth or other organic substances in the cooler well. The ability for the open system water cooler to spawn microbe growth is an acknowledged problem.

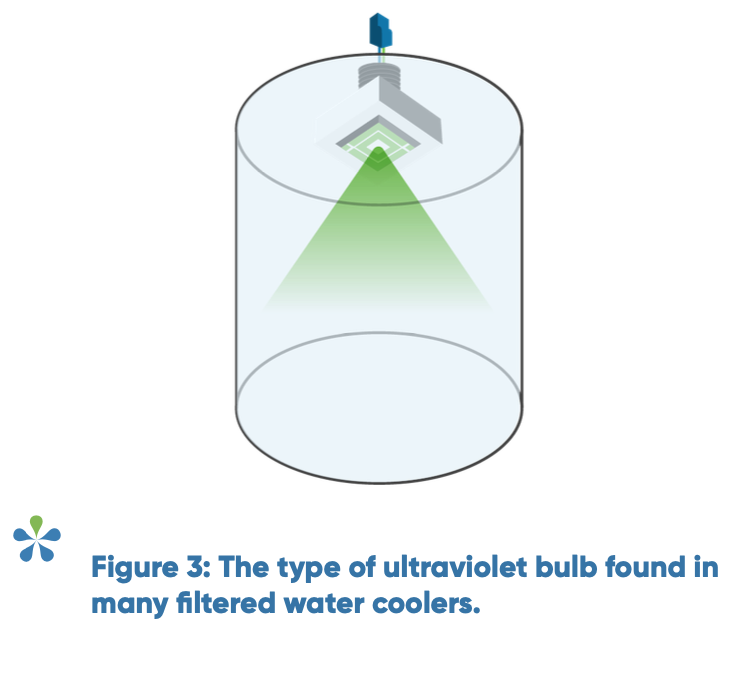

By contrast, filtered water coolers maintain an internal water supply and many use LED UV-C in machines to inactivate or kill microorganisms, without adding chemicals.

Many types of filtered water coolers sanitize your drinking water using internal ultraviolet light.

Source: Quench WHITE PAPER | How Bottleless Water Coolers Help Businesses Cut Costs, Improve Sustainability, and Enhance Employee Wellness

Take Your Hydration to the Next Level!

Learn more about Sierra Filtration Services Bottle Free Water Dispensers and our All Inclusive Rental Program at https://sierrafiltrationservices.com/bottle-free-water-dispensers/ and Call us at 1-800-951-3458 to request an appointment today.